Designing Structer

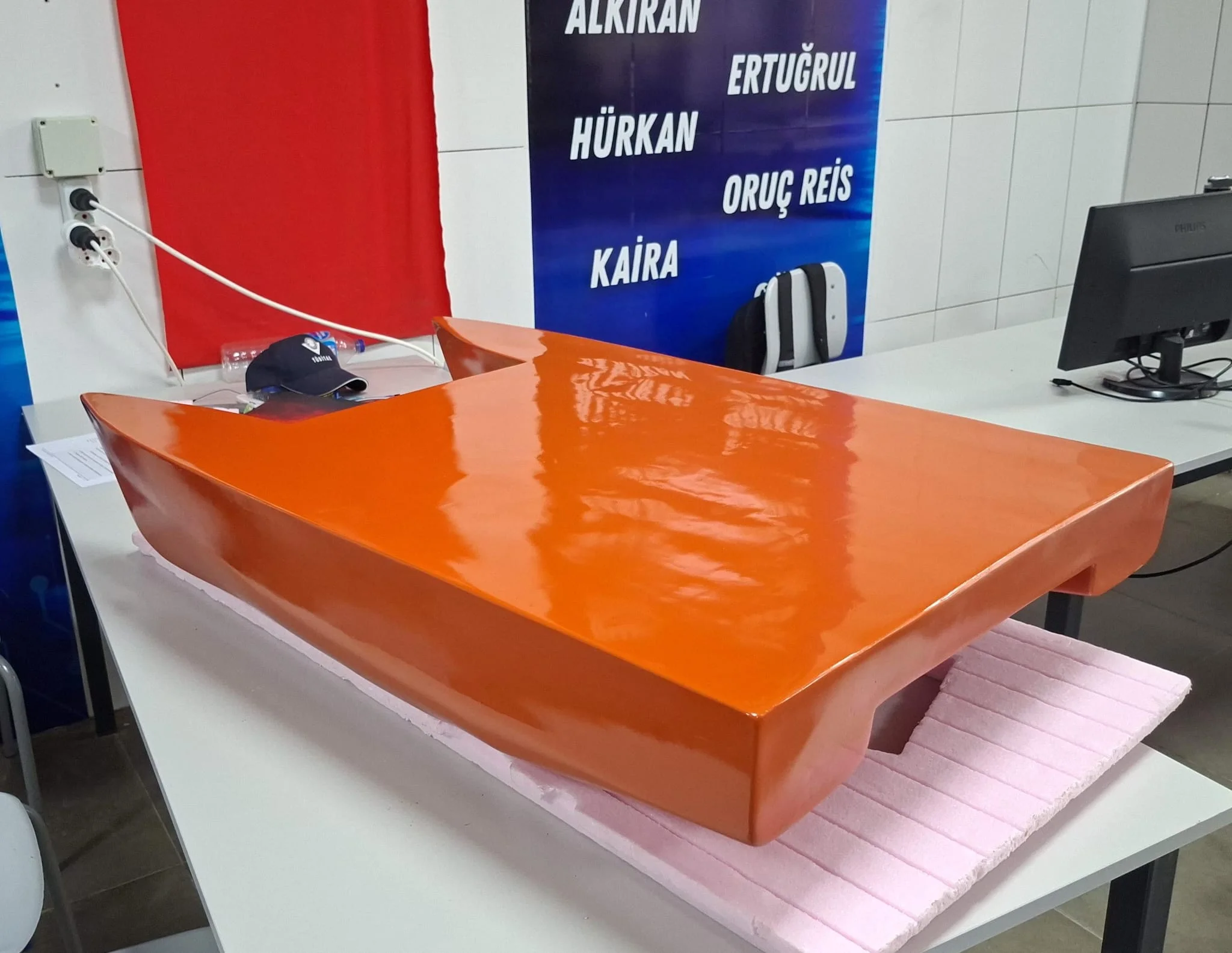

The autonomous catamaran was developed through a structured engineering process with a strong focus on reliability, performance, and readiness for competition environments such as RoboBoat. From the initial design phase, the primary goal was to create a platform that balances hydrodynamic efficiency with structural robustness, ensuring consistent operation under real-world racing and mission conditions.

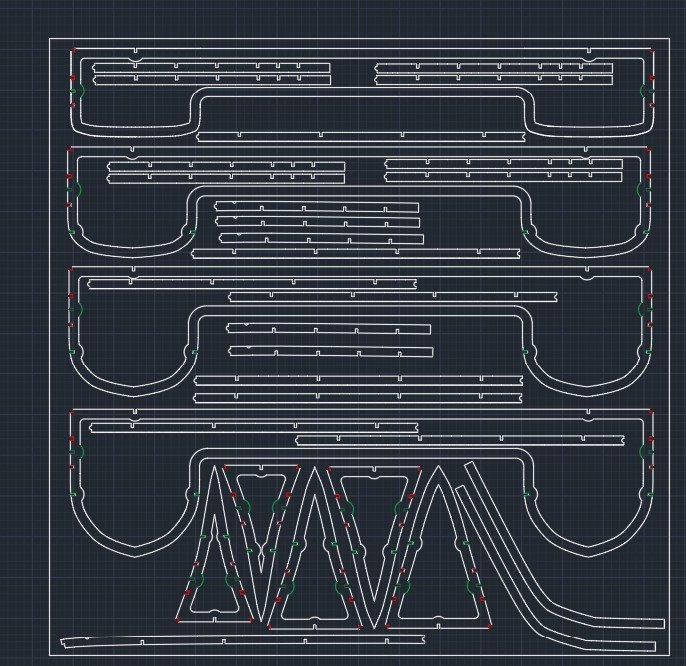

The design process began with the selection of a catamaran hull form to maximize stability, reduce hydrodynamic resistance, and provide a reliable base for autonomous navigation systems. Hydrodynamic performance and structural strength were treated as complementary but independently optimized aspects of the vehicle. This decoupled approach allowed the team to improve on-water behavior without compromising hull integrity or payload capacity.

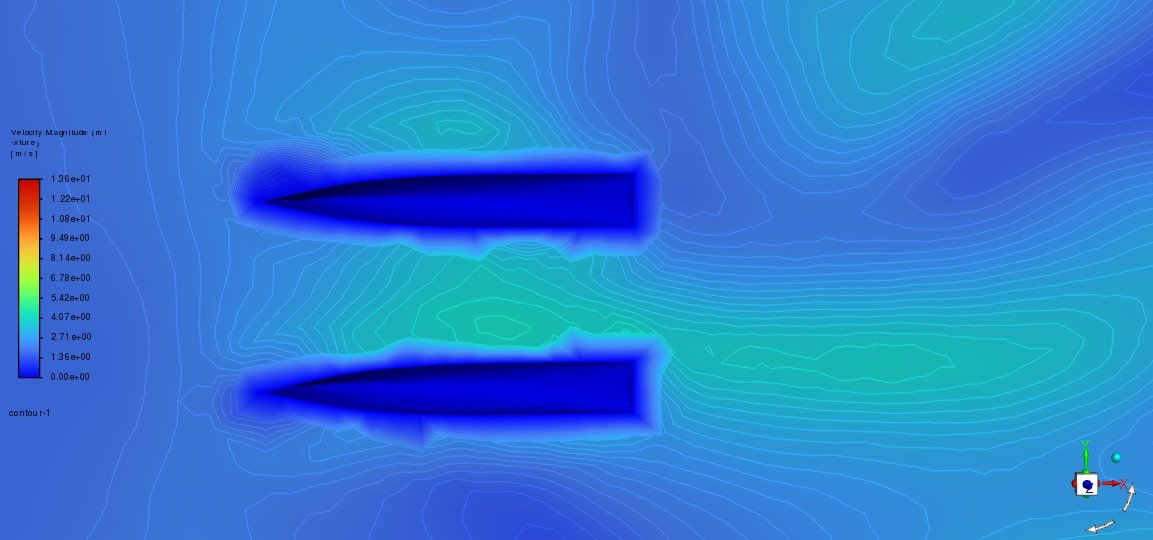

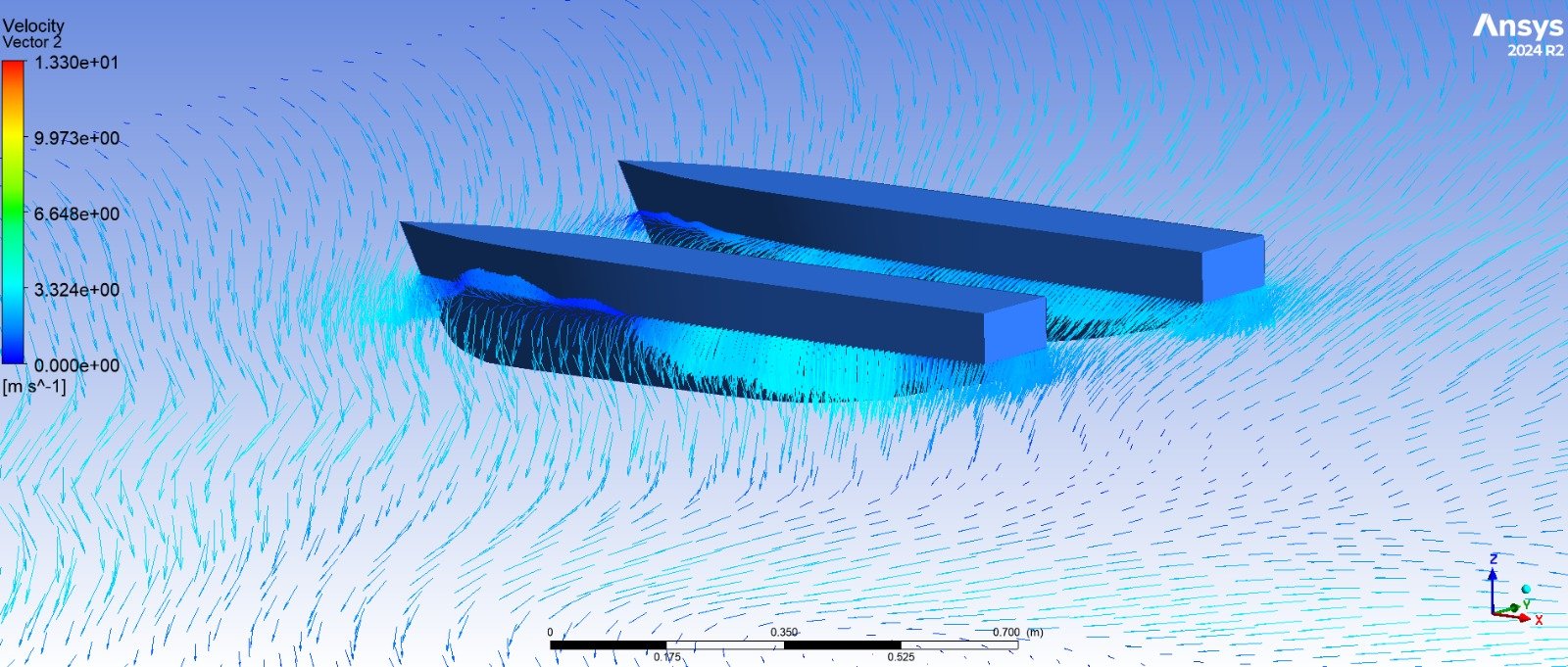

To support design decisions, comprehensive hydrodynamic and structural analyses were conducted throughout development. Hydrodynamic evaluations focused on stability, drag characteristics, and wave interaction, directly influencing hull geometry and spacing. In parallel, structural analyses assessed load distribution, stress concentrations, and deformation under expected operational and race-induced conditions. These analyses ensured that the vehicle could withstand dynamic forces encountered during high-speed maneuvers, environmental disturbances, and prolonged autonomous missions.

Insights gained from these simulations guided multiple design iterations, leading to targeted structural reinforcements and weight optimization. This iterative, analysis-driven process resulted in a platform that is both lightweight and mechanically resilient, aligning with the performance demands of RoboBoat missions.

The final design demonstrates a high level of engineering maturity. Analysis results confirm that the autonomous catamaran is stable, structurally safe, and capable of reliable operation in competitive racing scenarios. This development process reflects the team’s commitment to sound engineering principles, risk-aware design, and delivering a robust autonomous system ready for RoboBoat challenges and future scalability.

See Vehıcle in Action

The First Swim Test

Designing Thrower

The projectile launch system is inspired by the operating principles of tennis ball launching machines and is designed for reliable and repeatable target engagement. The system utilizes a controlled feeding mechanism that transfers projectiles smoothly from the storage section into the firing stage, ensuring consistent launch behavior. Special attention was given to mechanical balance, feeding angle, and transfer continuity to minimize jams and operational interruptions. Through careful optimization of the magazine geometry and firing interface, the system delivers stable and predictable performance, enabling accurate target engagement under dynamic mission conditions. This design prioritizes mechanical simplicity and reliability, making it well-suited for autonomous operation in competitive environments.

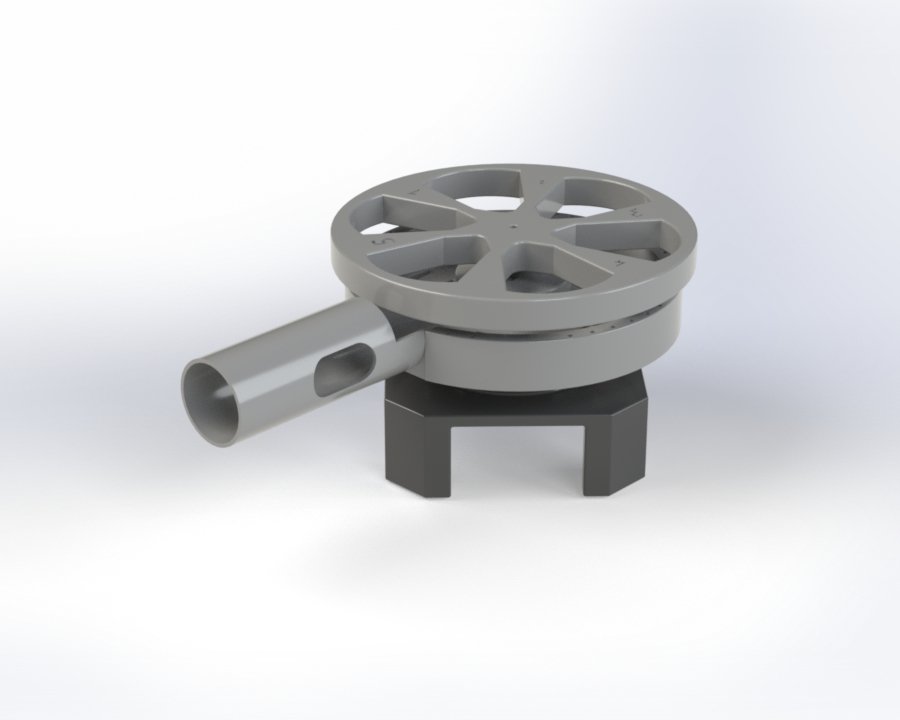

Version 1

The initial servo-controlled feeding mechanism was revised to address center of gravity instabilities and the mechanical complexity of the lower gear assembly, leading to a more optimized design.

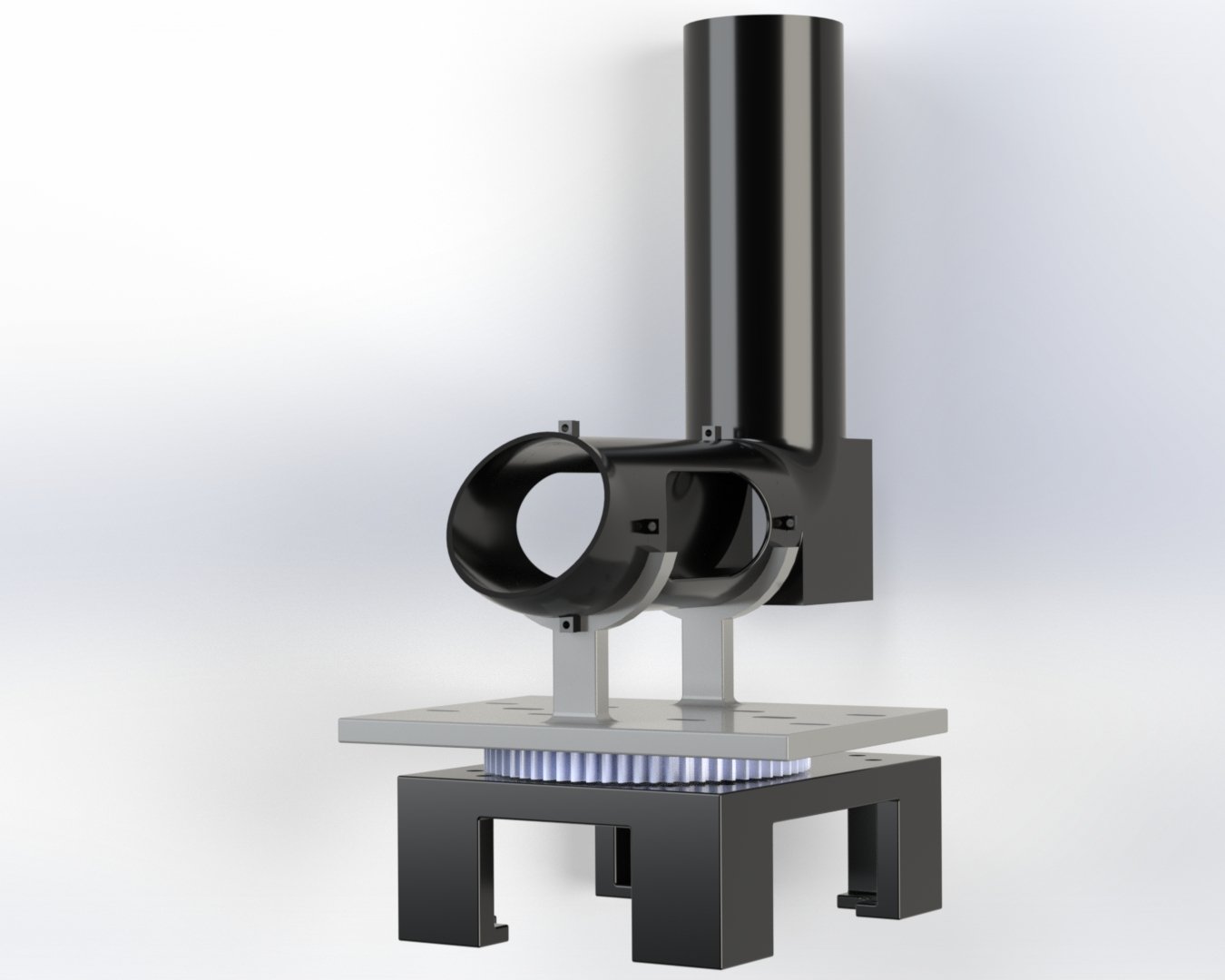

Version 2

Inconsistencies in the loading cycle, stemming from the steep incline of the magazine unit, necessitated a redesign of the storage section to rectify servo-gate malfunctions and ensure consistent firing performance.

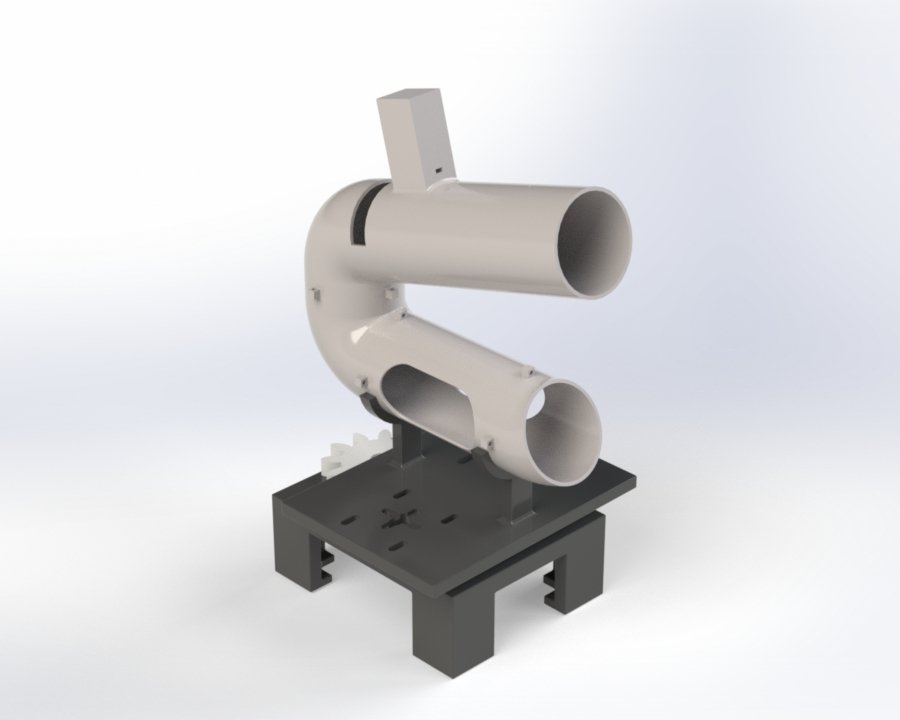

Version 3

Incorporating insights from previous iterations, the final design utilizes an optimized angled magazine system to ensure seamless projectile transfer. This configuration effectively resolves the mechanical inconsistencies of earlier prototypes, achieving the desired operational reliability.

See Thrower in Action

Thrower Test

Designing Mission Software

The autonomy software stack is developed using ROS 2 Humble and follows a modular, layered architecture that separates perception, navigation, and mission control responsibilities. The perception pipeline is built using YOLO-based deep learning models integrated with OpenCV for image processing and validation, while numerical computations and geometric transformations are handled using NumPy. Hardware-level communication, including actuator and microcontroller interfaces, is implemented via PySerial. This architecture allows individual subsystems to be independently tested, tuned, and reused across multiple RoboBoat tasks, ensuring robustness and scalability.

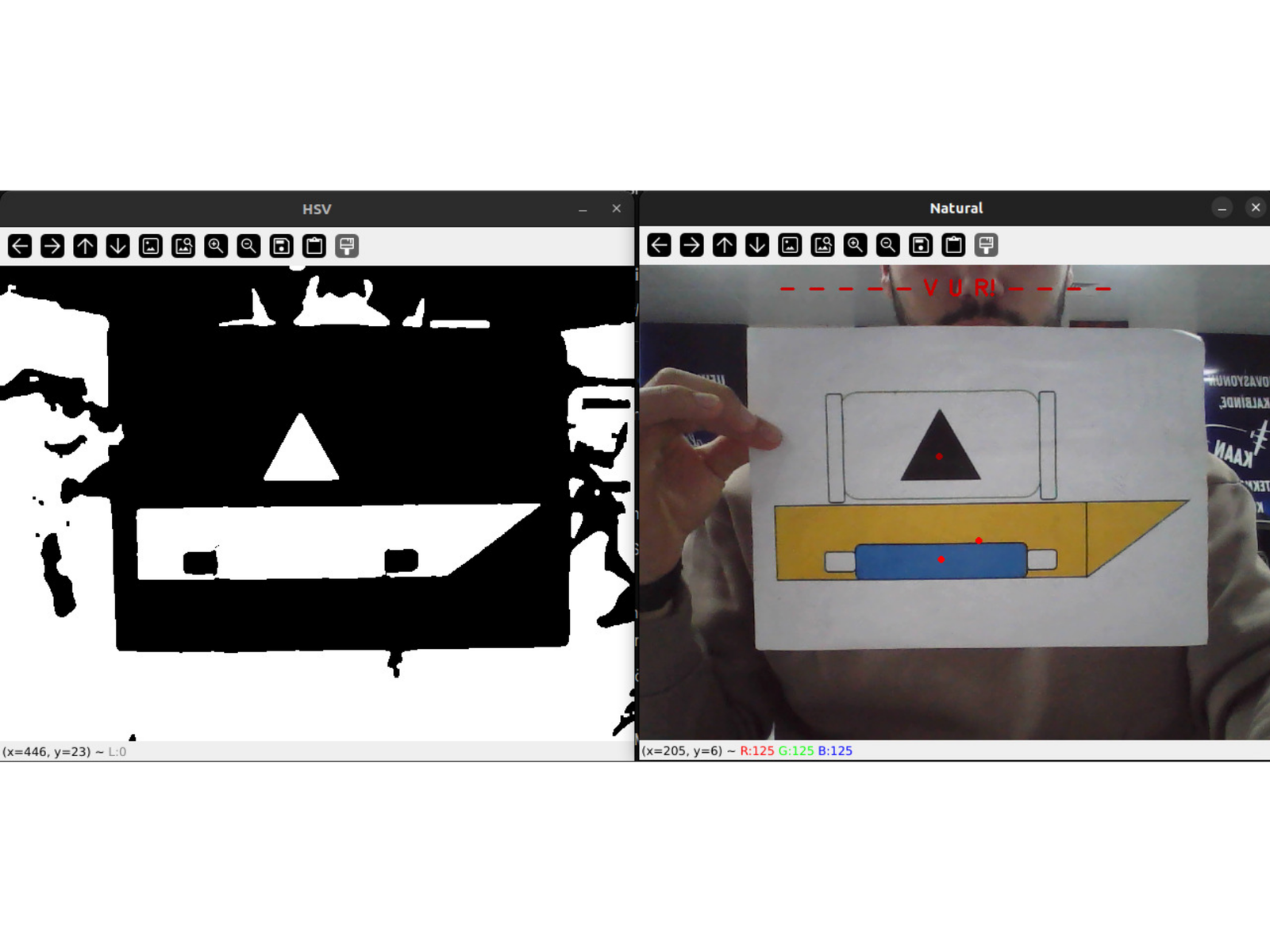

Vision System Development

The vision system is implemented as a modular perception pipeline based on deep learning (YOLO). Raw detections are filtered through confidence thresholds, geometric validation, and temporal stabilization to eliminate false positives.

To ensure stable behavior under real-world conditions, validated detections are passed through a fusion layer that associates and smooths object data over time. Only these fused targets are exposed to the autonomy system, preventing control instability caused by noisy perception.

Waypoint-Based Navigation System

The navigation system acts as an execution layer that converts autonomy decisions into controlled vehicle motion. It operates entirely on waypoint-based planning, enabling predictable and repeatable trajectories in marine environments.

The system continuously monitors task execution and vehicle behavior. In the event of path planning errors, perception loss, or unsafe conditions, it reliably transitions the vehicle into a safe-stop state.

Main Autonomy and FSM Architecture

At the core of the system lies a Finite State Machine (FSM) that synchronizes perception, navigation, and mission execution. Each task is implemented as an independent module interfacing with the FSM and returning atomic status values (Running, Success, Failure).

The FSM deterministically controls mission flow:

- Successful execution advances the mission

- Failures trigger recovery logic, retries, task skipping, or safe-stop states

This hierarchical state architecture ensures predictable behavior, simplifies debugging, and increases robustness under dynamic environmental conditions.

Testing, Simulation, and Validation

Before on-water trials, all algorithms are validated in a Gazebo simulation environment integrated with ROS. The simulation models vehicle dynamics, buoyancy, and sensor noise, allowing extensive testing of perception and control logic.

This process allows most software issues to be resolved before hardware integration, significantly reducing risk during competition runs.

Communication and Safety

The USV communicates with the Ground Control Station (GCS) via Wi-Fi, transmitting real-time telemetry, mission status, battery information, and live camera feeds.

For safety-critical operations, a redundant RF communication link provides hardware-level emergency stop (e-stop) and manual override capability, ensuring immediate intervention when required.